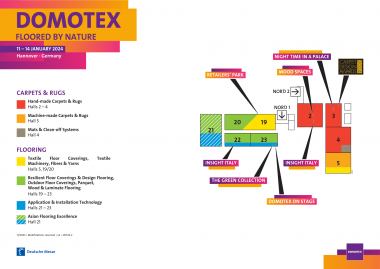

Over 1000 international exhibitors at DOMOTEX 2024

From 11 to 14 January 2024, the global carpet and flooring industry will meet at the Hannover exhibition grounds to discuss new products and current industry trends. With 1,000 international exhibitors, DOMOTEX promises a comprehensive overview of the Flooring und Carpets & Rugs sectors.

In addition to top exhibitors from the Carpets & Rugs sector, numerous global brands from the flooring industry will be exhibiting.

Well-known and long-standing exhibitors such as Area Floors, Amorim, Lamett, Li & Co, Camsan, Design Parquet, CFL Flooring, AGT, Forestry Timber, STP, SWISS KRONO, Decospan, Massive Holding, Floorify and Granorte have confirmed their participation. However, new exhibitors or those who have not participated for several years are also back in 2024 – including Kronospan and Kaindl, mFlor, Onefloor, Republic, Classen, Gerflor and MeisterWerke. From the field of application and installation technology, Neuhofer, SELIT, Välinge, Estillon, Shaper Origin, ADESIV, KLEIBERIT and i4F have also announced their participation.

In addition to the main exhibition, DOMOTEX will offer a variety of side events designed to provide important impulses for the day-to-day business of all trade visitors

THE GREEN COLLECTION

For the second time, THE GREEN COLLECTION in Hall 23 will highlight the latest developments in the fields of sustainability, circular economy and environmental protection in the carpet and flooring industry for visitors to experience first-hand. The special display includes current research projects by TFI Aachen, a haptic material show by raumprobe and product presentations by companies such as Uzin Utz, Classen and Gerflor.

RETAILERS‘ PARK

In collaboration with DECOR-UNION and the MEGA Group, DOMOTEX will be expanding its portfolio to include the two product segments "wall" and "ceiling" for the first time. In addition to other flooring suppliers, the RETAILERS' PARK in Hall 19/20 will feature products for holistic interior design, including paints and coatings from Südwest, Meffert and PPG Coatings as well as wallpapers from AS and Erfurt. Participants can also look forward to practical solutions for their day-to-day business, presented in the area's own user forum through hands-on live demonstrations.

DOMOTEX on Stage

The conference program in Hall 23 features experts from the retail sector, associations, architecture, interior design, trade and politics, who will offer a holistic view of the topics of the future for the entire industry. On Friday, 12 January, German politician and member of the European Parliament Reinhard Bütikofer will give a presentation on the European Green Deal. Joachim Stumpp, Managing Director of raumprobe, and Chiara Rodriguez from Materially will report on sustainable materials. In addition to sustainability, topics relating to trends, new work and the shortage of skilled workers will also play a keyrole at DOMOTEX on Stage.

Deutsche Messe AG