Airborne strengthens its activities in the D-A-CH region with AMAC

As of October 1st, 2019, the Netherlands-based global market leading manufacturer of advanced automation equipment and solutions for composites, Airborne, strengthens its activities particularly in German speaking countries, the so-called D-A-CH region, comprising Germany, Austria and Switzerland with Dr. Michael Effing from AMAC. The Dutch company is looking for specialised partnerships to develop and deepen its international business opportunities in the aerospace and automotive markets.

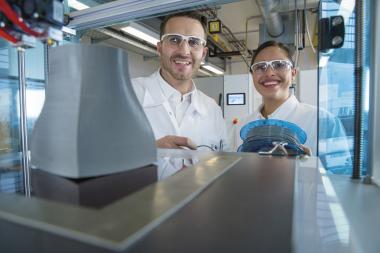

Airborne’s focus is on high-end composite components, at high production rates at radically low conversion costs. Airborne is building up a suite of automated solutions for the manufacturing of composites with the aim to radically reduce costs and touch labour, minimize the footprint and use of material, and improve the time to market for their clients. The company offers i.a. solutions in automated honeycomb potting, automated kitting and automated lamination of thermosets and thermoplastics. In order to develop new business opportunities in the D-A-CH region for the end-markets aerospace and automotive, Airborne is cooperating with AMAC to accelerate the process of locating suitable partnerships.

Dr. Effing, CEO of AMAC GmbH confirms: "As a first step for the establishment of Airborne on the German market, we just signed their membership at AZL in Aachen which will help to connect with over 80 companies and latest research developments. In the framework of theirstrategy to strengthen the supply to the aircraft sector, Airborne will also exhibit at the Aircraft Interiors Expo in Hamburg from March 31st to April 2nd 2020.”

AMAC GmbH