IDEA®22 with a Vital World View of Nonwovens

- Expert Speakers Delivering Key Region Market Updates

Industry leaders will gain a compelling region-by-region view of the nonwovens industry from experts presenting the latest nonwovens trends in their areas of the world at IDEA®22, March 29-31 in Miami Beach.

Speakers with the latest knowledge will deliver important nonwoven market updates, demand forecasts and research findings on the industry in China, Asia, South America, North America and Europe.

The conference will explore how each region has responded to the pandemic challenges and supply chain issues with new innovations and solutions, providing IDEA® attendees with vital insights for decision-making.

Program highlights include:

- Overview and Green Innovation Development of China’s Nonwovens Industry, by Guimei Li, Vice President, China Nonwovens and Industrial Textiles Association (CNITA) on March 29

- South America – Land of Opportunity or Land of Turbulence? The Recent History and Trends That Are Shaping the South American Nonwovens Market, presented by Mariana Mynarski, Corporate Marketing Manager, Fitesa on March 29

- Asian Nonwovens Production and Market Update by Chan-Hyou Park, Chairman, Asia Nonwoven Fabrics Association (ANFA) on March 30

- Understanding the State of the North American Nonwovens Industry and a Market Gone Mad presented by Brad Kalil, INDA Director of Market Intelligence and Economic Insights on March 31

- An Overview of Key Issues Facing Nonwovens on Top of European Market Trends presented by Pierre Wiertz, General Manager, EDANA on March 31

IDEA® Award Presentations

Another conference highlight will be the presentation of the IDEA® 2022 Achievement Awards in partnership with Nonwovens Industry magazine, based on the results of online voting in six categories as well as the announcement of the first Sustainability Advancement Award on March 30.

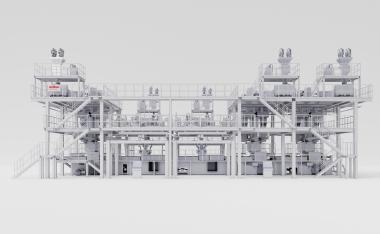

IDEA® – the World’s Preeminent Event for the Nonwovens & Engineered Fabrics Industry – will feature several hundred exhibitors from a myriad of industry sectors and is expected to once again draw an audience of several thousand senior-level buyers and attendees from over 60 countries to the Miami Beach Convention Center. A welcome reception will be held to officially kick off the event on March 28.

IDEA®22 Essentials of Nonwovens Training Courses

Product developers, marketing managers, technical sales, support and other professionals can expand their industry-focused knowledge by attending the IDEA®22 Essentials of Nonwovens Training Courses.

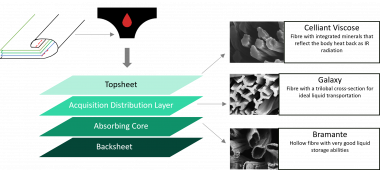

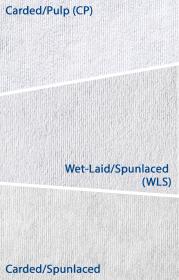

This vital training program will provide an immersive dive into the latest nonwoven technologies, industry segments and more with courses on absorbent hygiene cores, making nonwovens, industrial wipes and consumer wipes.

A must-attend educational session on patent searching on March 31 will cover the latest major changes in patent searches on the United States Patent and Trademark Office (USPTO) website that has been updated to enhance user experience.

IDEA