SHIMA SEIKI at FIMEC 2024 in Brazil

SHIMA SEIKI MFG., LTD. of Wakayama, Japan, will together with its Brazilian representative BRASTEMA TECNOLOGIA TEXTIL LTDA. participate in the FIMEC 2024 47th International Fair of Leather, Chemicals, Components, Machines and Equipment for Footwear and Tanneries in Rio Grande do Sul, Brazil from 12th - 14th March 2024.

FIMEC offers the opportunity to reach out to the Brazilian shoe manufacturing industry with proposals for flat knitted fabrics as an alternative to conventional leather. Since participating in FIMEC over the years, SHIMA SEIKI has steadily expanded its market for shoe-upper knitting machines in Brazil. It will be showcasing its latest computerized flat knitting technology to demonstrate how they apply to footwear and other sportswear as well.

The company is showing its new SWG-XR® WHOLEGARMENT® knitting machine for the first time in Brazil. SWG-XR® features 4 needle beds and SHIMA SEIKI’s original SlideNeedle™, capable of producing high-quality fine gauge WHOLEGARMENT® products in all needles, and will be knitting WHOLEGARMENT® sportswear at FIMEC. For conventional shaped knitting, the compact SVR®093 machine with a short knitting width is specially developed for knitting shoe uppers, while the workhorse N.SSR®112 shaping machine features the latest garment knitting technology in an economical yet reliable package.

Both SVR®093 and N.SSR®112 will be knitting shoe uppers at FIMEC while utilizing the R2CARRIAGE®, WideGauge® knitting, spring-type moveable sinker, DSCS® Digital Stitch Control System, stitch presser, yarn gripper and cutter, and takedown comb. The classic SFG® seamless glove knitting machine will be knitting safety-oriented work gloves to round out SHIMA SEIKI’s multi-faceted display.

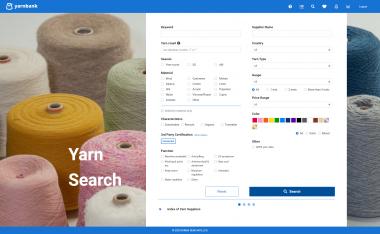

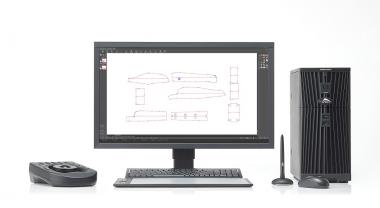

SHIMA SEIKI’s SDS®-ONE APEX4 3D design system will also be available for demonstrations in design

and simulation suited to shoe production.

SHIMA SEIKI MFG., LTD