Stratasys unveils D2G solution with Urban Tattoo denim collection

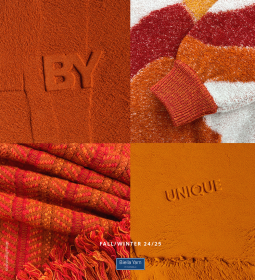

Stratasys Ltd. announced the launch of its Direct-to-Garment (D2G) solution for the J850 TechStyle™ printer, the newest offering in the Stratasys 3DFashion™ direct-to-textile printing technology. The first example of its application is an Urban Tattoo denim collection which will be revealed at the Texprocess exhibition in Frankfurt, Germany on April 23.

The D2G solution is ideal for customization and personalization by enabling the application of full color multi-material 3D print directly on fully assembled garments of various fabric types including denim, cotton, polyester, and linen. It allows fashion brands to facilitate personalized and bespoke designs for customers, including the ability to tailor 3D prints according to individual preferences, sizes, and styles.

Available in two sizes, the D2G tray kits facilitate the personalization of garments ranging from jeans to jackets, enabling designers and manufacturers to adopt more sustainable practices by reducing material waste. The seamless workflow delivers ease of calibration and compatibility with various garment sizes, streamlining the production process and fostering the creation of unique, personalized apparel.

Demonstrating this innovation, the Urban Tattoo collection showcases the potential and the ease of direct-to-garment 3D printing. Working with noted designers Karim Rashid, Travis Fitch, Zlatko Yanakiev at Meshroom along with Foraeva Studio, this collection shows the transformation of ordinary garments into pieces of wearable art, imbuing them with personal identity and meaning.

Like body tattoos, Urban Tattoos promote a deeper emotional connection, encouraging the upcycling of existing garments and contributing to a more sustainable fashion ecosystem. This aligns with Stratasys’ strategy for Mindful Manufacturing™. Stratasys has been able to create a new collection that will appeal to multiple brands that reach across diverse socio-economic backgrounds.

Stratasys Ltd