Monforts denim mills move hemp into the mainstream

- There is an urban legend that hemp canvas was used to make the very first pair of Levi’s jeans.

- While this is a myth that originated in the counterculture of the 1960s, hemp is without doubt the fibre of the moment for the denim industry.

At the second Kingpins24 virtual denim show that was broadcast from New York on June 23rd and 24th, the sustainable benefits of hemp fibre were referenced by many Monforts customers who are now including it in their collections, including AGI Denim, Artistic Milliners, Black Peony, Calik, Cone Denim, Naveena Denim Mills (NDM) and Orta.

“Hemp is an easy to grow fibre which requires no irrigation, no fertilizers, no herbicides and no chemicals,” says Allan Little, Director of Product Development for Cone Denim, which has recently launched its Sweet Leaf collection featuring the fibre. “Significantly, it also uses fifty per cent or even less water than cotton in cultivation.”

It can also bring some new aesthetics to denim too, he adds.

“Hemp has a unique colour and adds a different cast to our indigo, the drape and texture of the fabrics is different and it even adds a bit of a unique hand, so combined with its sustainable credentials we are proud to be bringing the Sweet Leaf collection to the market.”

US supply chain

Cone is currently sourcing its hemp from France, but with much of its manufacturing now in Mexico – and with the introduction of the US Farm Bill in 2018 which has legalised the growing of legal hemp – is exploring the possibility of investing in the US supply chain.

“With US hemp we’re really at the R&D phase,” Little emphasises. “It’s a unique crop, so coming up with the right stalk to provide the right fibre is challenging. We’ve experimented with different types of seed and various methods of decortication.”

Decortication, he explains, is the mechanical removal of the outside layer of the hemp stalk to useable fibre on the inside. A second process, cottonization, is necessary to make the fibre suitable for spinning, because compared to cotton, hemp is longer, stiffer, and less flexible.

100% success

At the end of 2019, Naveena (NDM), headquartered in Karachi, introduced fabrics featuring up to 51% hemp content in blends with Tencel and recycled polyester and this year has developed the first 100% hemp denims.

“The response to the fabrics we showed last year was incredible and we were looking forward to the response to this latest development – which everyone was asking for – at the Kingpins show in Amsterdam, which unfortunately was unable to go ahead,” says NDM’s Director of Marketing Rashid Iqbal. “We produced initial samples in an undyed state because we were not sure how the wet spun yarn would react in the dyeing, but I’m happy to say we have had success in this respect and are now able to provide one hundred per cent indigo dyed hemp denim.”

Environmental benefits

“Differentiation is the key in the highly-competitive denim industry and we have assisted our customers with trials and optimised processing parameters for a range of different fibres, including hemp, both at our Advanced Technology Centre in Germany and at their own mills around the world,” says Hans Wroblowski, Monforts Head of Denim. “Given the environmental benefits of hemp, and the liberalisation of its cultivation in many parts of the world, the interest in it now comes as no surprise. We have the technologies and know-how to help our customers to fully maximise their hemp denims at all post-weaving stages of production.”

Monforts has a dominant position in the field of denim finishing with its well proven Montex stenters. It has been enjoying further recent success with its Eco Line concept based on two key technology advances – the Eco Applicator and the Thermo Stretch.

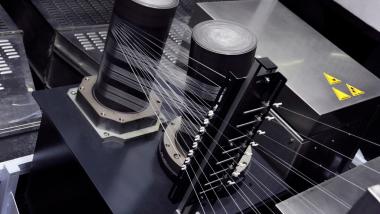

The latest Monforts innovation for denim is the CYD yarn dyeing system. This technology is based on the effective and established dyeing process for denim fabrics that is now being applied for yarn dyeing.

The CYD system also integrates new functions and processes into the weaving preparation processes – spinning, direct beaming, warping and assembly beaming, followed by sizing and dyeing – to increase quality, flexibility, economic viability and productivity. A full CYD line is now available for trials at the company’s Advanced Technology Centre.