Kornit Digital introduces Smart Curing and Rapid SizeShifter at TecStyle Visions 2023

Kornit Digital LTD. announced to unveil its new Smart Curing and Rapid SizeShifter solutions at TecStyle Visions 2023. Kornit Smart Curing is an intelligent and adaptive solution significantly streamlining curing processes while delivering high-quality results. Additionally, the introduction of Rapid SizeShifter eliminates time-consuming direct-to-garment pallet changes typically required to address disparate applications.

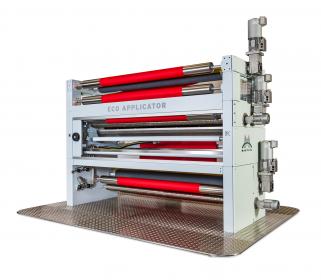

Kornit’s new energy-efficient Smart Curing solutions include Orion for mid-level production, and Titan for higher-capacity volumes – both optimized for compatibility with Kornit Atlas MAX systems and based on field-proven solutions from the acquisition of Tesoma. These highly efficient curing systems sync production and finishing for an end-to-end process that reduces both energy consumption and total cost of ownership (TCO). Kornit’s Rapid SizeShifter for Atlas MAX is an adjustable pallet that quickly adapts to disparate application requirements – reducing costly downtime associated with pallet changes and streamlining production for accelerated time-to-market.

Kornit Digital LTD.