Winner of the Cellulose Fibre Innovation of the Year

The annual highlight of the industry is the International Conference on Cellulose Fibres in Cologne, where the latest innovations were showcased: new cellulose fibre technologies for various feedstocks and a wide range of hygiene and textile products as well as alternatives to plastics and carbon fibre for lightweight constructions.

This year, for the first time, there were 230 participants from 27 countries. About 60 were able to attend on site – with strict Corona safety measures – while the others were able to attend online and participate in questions and discussions.

The conference gave deep insights into the promising future of cellulose fibres, which fit perfectly into the current trends of circular economy, recycling and sustainable carbon cycles.

An important focus at the conference was alternative sources of cellulose. The increasing demand for cellulose fibres cannot be met in the long run with wood and used textiles alone. At the conference, a variety of agricultural by-products and biogenic waste were presented in presentations and panel discussions, such as orange and banana peels, grain and hemp straw. Much of this is high-volume and has not been put to high-value use so far. Exciting opportunities for the future cellulose fibre industry.

Innovation Award

Live at the conference, host nova-Institute and award sponsor GIG Karasek GmbH granted the “Cellulose Fibre Innovation of the Year” award to one of six highly interesting products.

- First Winner: Carbon Fibres from Wood – German Institutes of Textile and Fiber Research Denkendorf (Germany)

- Second Winner: Fibers365, Truly Carbon-Negative Virgin Fibres from Straw - Fibers365 (Germany)

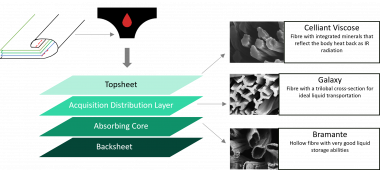

- Third Winner: Sustainable Menstruation Panties: Application-driven Fibre Functionalisation – Kelheim Fibres (Germany)

nova-Institut cellulose fiber International Conference on Cellulose Fibres Cellulose Fibre Innovation Sustainability

nova-Institut GmbH