Hohenstein celebrates 30 years of accreditation

On June 9, Hohenstein celebrates World Accreditation Day (WAD2023) along with 30 years as an accredited testing laboratory. In 1993, Hohenstein’s first lab received official certification to test textile products competently, reliably and impartially according to internationally recognized standards. With the expansion of its testing business, the company, headquartered in Boennigheim, Germany, has since gained numerous other accreditations for its global laboratories.

"The accreditations give our customers confidence that we comply with the required quality control procedures," says Julia Seeberg, who as Head of Quality Management also oversees the regular monitoring of the laboratories by DAkkS, the Deutsche Akkreditierungsstelle. “Everything possible is done to ensure the integrity of the test results.” In addition to DAkks accreditations of the testing laboratories for textile technological, biological, chemical and physical tests, Hohenstein is accredited as a certification and inspection body. Hohenstein's 75 years of expertise in the testing business complement its accreditation and provide an important basis for its long-standing customer trust.

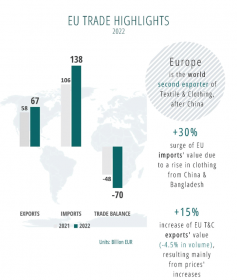

Hohenstein laboratories in China, Bangladesh, Hong Kong and India have accreditations from the respective national and international accreditation bodies. The labs celebrate World Accreditation Day by highlighting the importance of accredited laboratories for the product quality and sustainability. "The demands of suppliers and consumers have increased," Julia Seeberg also notes. “For manufacturers to remain credible, it is even more imperative to demonstrate compliance with defined and standardized quality criteria.”

The globally valid quality standard for testing and calibration laboratories is DIN EN ISO/IEC 17025. The standard specifies general requirements for the competence, impartiality and uniform working methods of laboratories that operate internationally. Accreditations in accordance with DIN EN ISO/IEC 17020 and 17065 exist for the inspection and certification bodies. In addition, Hohenstein is an accredited testing laboratory for medical devices, where biological, chemical and physical laboratory tests are carried out. These tests form the basis for conformity with the European Medical Device Regulation (MDR).

Hohenstein