Sappi: Expanded production options for Fusion Topliner

Sappi, a leading provider of sustainable woodfibre-based packaging materials, is expanding production of its successful Fusion Topliner grade to its flagship mill in Gratkorn, Austria. The Fusion Topliner – a white virgin fibre liner for high-quality corrugated packaging – will also continue to be manufactured at Sappi’s Ehingen mill in Germany. With this project, Sappi isn’t just expanding its production capacity in the corrugated board business. By offering the same product quality from both mills, Sappi is bringing production closer to its customers – to guarantee a sustainable and short supply chain in the heart of Europe.

- Sappi’s Fusion Topliner virgin fibre liner strengthens brand image and impact, and demand continues to grow

- Capacities are now being expanded through significant investment at Gratkorn mill, Austria

- Volumes will be enlarged in the next months to ensure reliable customer supply

Just a decade ago, there were only two options on the market for coated white corrugated liners: either kraft liner made from high-quality raw materials and with a very low recycled content, or test liner, which consists almost exclusively of recycled paper. As an alternative, Sappi developed its Fusion Topliner, now the most widely used corrugated liner made from pure virgin fibre. It is recommended for applications such as premium quality consumer goods packaging and POS displays – where high visual impact and differentiation are key. The product also stands out with exceptional strength and versatility.

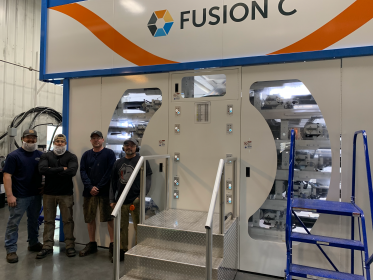

Sappi’s Fusion Topliner has been successful on the market for many years. Demand for the product has continued to grow, due to its exceptional characteristics for print quality and finishing. Production is now being expanded from the German mill in Ehingen to include Sappi’s flagship mill in Gratkorn. The available capacities are now being expanded to include the production of Fusion Topliner in addition to existing graphic papers. Volume availability will be increased month by month to support the expected growth of our customers, and to satisfy large requirements in the corrugated board business.

Sappi Europe / Ruess Group