Mimaki supports Printers Worldwide in Global Innovation Days Event

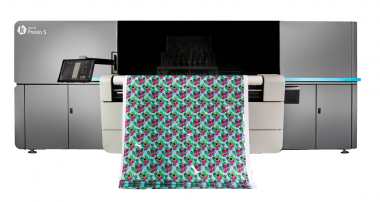

Mimaki held their global event Innovation Days (2-4 June 2021) to great success. The event brought together printers, journalists and experts from Mimaki Japan, USA and Europe, to nurture innovation in the sign graphics, industrial, textile and 3D markets and drive success within the industry. The global event also introduced the market to Mimaki’s recent product releases, the JFX550, JFX600 and SUJV-160.

In a week of webinars, workshops, demonstrations, and networking events, over 1,300 attendees from all across the world logged in to participate, with the demonstration of UJV100 and JV100 printers, 3D printing workshop and car wrap workshop being the most popular events. As a first of its kind for Mimaki, visitors were able to speak with regional Mimaki representatives, gaining greater insight into the global printing industry as it recovers from the COVID-19 pandemic.

A stand-out attraction of the event was the recently released 100 Series, which is priced affordably to allow printers entry into different markets, as many look to expand their portfolio in these uncertain times. The new JFX600-2513 and JFX550-2513, which debuted a few weeks prior at virtual drupa, similarly are higher end but still affordable printers, when compared to other large format UV flatbed machines in its class. 3D full colour print technology also featured heavily in the event, as Mimaki explored the exciting propositions it opens up in different markets and how the brand continues to extend the reach and accessibility of cutting-edge 3D technologies with its upcoming 3DUJ-2207 printer.

Mr. Kazuaki Ikeda, President of Mimaki Engineering commented, “I’d like to extend my thanks to everyone who joined us during this exciting new virtual event. During the pandemic, carrying on innovating has been central to Mimaki’s objectives, with eight new products having been released since October, and even more scheduled to come out over the course of this year. I hope that we can soon all meet at in-person events, once it’s safe to do so, but until then I’m excited to see the results of the continued collaboration and innovation of print industry that we saw in our Innovation Days event.”

Mimaki Mimaki Europe textile printer digital printer inkjet digital printer 3D printing

EMEA, Mimaki Europe B.V