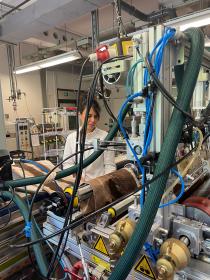

Panda Biotech Marks Final Stage Commissioning

Panda Biotech announced that building construction is complete and the official commissioning process to bring its Panda High Plains Hemp Gin™ (the “Panda Hemp Gin”) project online began in early Q4. The commissioning process marks the final stage before beginning commercial operations in Q1 2024 at the 500,000 square foot Wichita Falls, Texas facility. The Panda Hemp Gin will process 10 metric tons of industrial hemp per hour to produce textile-grade fiber, hurd, short-fiber hurd mix, and a nutrient-rich co-product that will be pelletized. The facility is expected to be the largest hemp decortication center in the Western Hemisphere and among the largest in the world.

Using only renewable energy sources, the engineering and production process at the Panda Hemp Gin has been certified green by Mid-South Engineering Company, in accordance with the International Capital Market Association’s Green Bond Principles. Panda Biotech has also partnered with Oritain, a scientific traceability company, to bring the most traceable hemp grown 100 percent in the United States to market.

Additionally, Panda Biotech is actively signing contracts with producers to grow the hemp feedstock for the 2024 growing season, as well as purchasing hemp fiber that has already been harvested or processed. The company recently unveiled an unmatched pay-to-grow program for producers to begin growing Panda hemp. With up-front, guaranteed money and agronomy support, Panda producers also receive tested and proven seed at no cost, successfully mitigating the risk producers may assume and underscoring Panda’s commitment and promise to the farming community. The benefits of growing hemp are substantial, as it is an excellent rotational crop that remediates the soil and provides a competitive margin.

“Each piece of the Panda Hemp Gin production line, including the three miles of overhead pneumatic duct lines, refining, blending, mechanical cottonization, hurd bagging and storage, baling, and more, must be individually started, checked, balanced, and commissioned,” says Panda Biotech Executive Vice President Scott Evans. “Currently, all equipment is individually being brought online to be officially placed in service.”

Panda Biotech, LLC.