Legacy Flexo invests in second Fusion C press from PCMC

- Flexographic printing press includes award-winning SteadyPrint anti-bounce technology

Paper Converting Machine Company (PCMC), part of Barry-Wehmiller, has announced the sale of a second Fusion C printing press to Legacy Flexo Corp. in Green Bay. “We are excited to be purchasing a second Fusion C flexographic press,” said Dan Aberly, Operations and Sales, Legacy Flexo. “We’ve experienced a lot of success with our first Fusion C, which has allowed us to offer our customers more efficient runs. The fact that PCMC has been a true partner with us, providing exceptional quality and service, and is local to us were also deciding factors.”

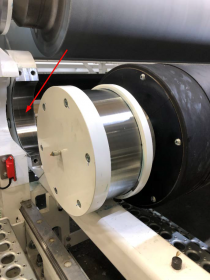

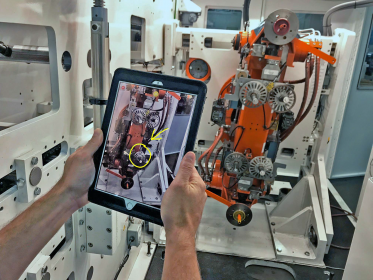

The Fusion C has a smaller footprint with fewer parts, but incorporates many fast make-ready and waste-saving features, including the innovative SteadyPrint technology. Winner of the 2019 FTA Technical Innovation Award, SteadyPrint significantly reduces the effects of bounce when printing graphics with hard edges due to its bearing arrangement, which is coupled with an algorithm utilizing noise-canceling technology. With patents pending on all features, SteadyPrint is currently the only product on the market using this kind of technology to eliminate disturbances and provide real-time monitoring.

Paper Converting Machine Company PCMC