Rieter completes acquisition of the three Saurer businesses

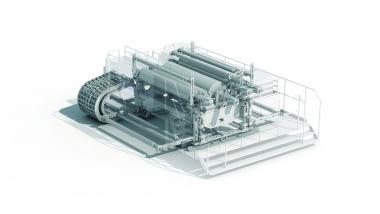

With the takeover of the automatic winding machine business at the Uebach-Palenberg/Germany site with effect from April 1, 2022, Rieter has completed the acquisition of the three businesses from Saurer.

The acquisition of the automatic winding technology in the premium category completes Rieter’s ring and compact-spinning system and thus lays the foundation to further improve the company’s position in the staple fiber market segment.

The components businesses Accotex (elastomer technology for spinning machines) at the Muenster/Germany site and Temco (technology components for filament machines) at the Hammelburg/Germany site had already been acquired by Rieter as of December 1, 2021.

Rieter had announced the acquisition of the three businesses on August 16, 2021.

In total, the three businesses generated sales of EUR 142 million in 2020, the year of the COVID crisis. In 2019 and 2018, total sales amounted to EUR 235 million and EUR 260 million, respectively.

The winding machine business with new machines will be assigned to the Business Group Machines & Systems, and the after-sales business will be assigned to the Business Group After Sales. The Accotex and Temco component businesses are managed by the Business Group Components.