Recycled carbon fiber: When a Boeing 787 turns into a Lenovo ThinkPad

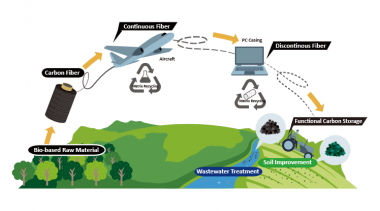

Toray Industries, Inc. announced the successful development of recycled carbon fiber (rCF) derived from the production process of the Boeing 787 components using Toray’s advanced carbon fiber, TORAYCA™. The rCF, which is based on pyrolysis recycling process, has been integrated into the Lenovo ThinkPad X1 Carbon Gen 12 as reinforcement filler for thermoplastic pellets. Toray and Lenovo will continue to collaborate to expand the usage of rCF in other Lenovo products.

Toray rCF is the outcome of Boeing and Lenovo’s shared commitment to minimize their environmental impact. Boeing’s objective is to reduce solid waste going to landfill and produce recyclable materials, while Lenovo has been exploring materials to reduce the carbon footprint of their products. Toray rCF connects these visions by repurposing Toray’s high-performance carbon fiber from the Boeing aircraft production process into Lenovo’s ultra-light laptop PC.

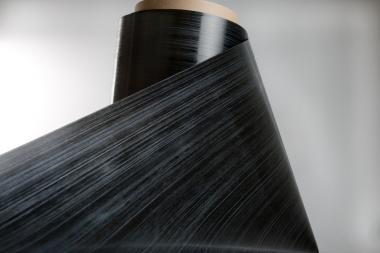

TORAYCA™ is an established aerospace material known for its high strength, stiffness, and lightweighting properties. These qualities have led to its adoption in other applications such as electrical and electronic equipment housings, sports equipment, and other industrial applications.

A key advantage of carbon fiber is the ability to retain its primary mechanical properties even after the recycling process. Toray is actively advancing recycling technologies and establishing a strategic business model for rCF. Given that the carbon footprint of rCF is lower than that of virgin carbon fiber, Toray is proactively recommending the adoption of rCF to reduce the environmental impact of customers’ products. This commitment aligns with Toray’s dedication to fostering a circular economy, thereby reducing landfill waste.

Toray Industries