Call for Papers ADD-ITC 2024

The next AACHEN-DRESDEN-DENKENDORF INTERNATIONAL TEXTILE CONFERENCE will take place on November 21/22 2024 in Stuttgart on site.

You are invited to submit abstracts for oral or poster presentations related to the following topics:

- Textile Mechanical Engineering

- Biobased Fibers

- High Performance Fibers

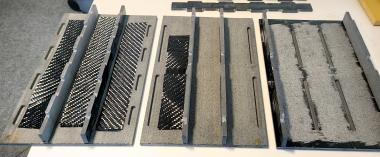

- Fiber Composites and Lightweight Construction

- Circular Economy and Recycling

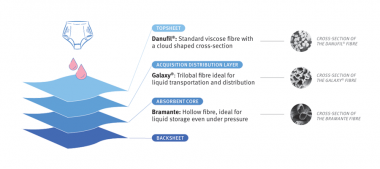

- Medicine and Health

- Functionalization and Finishing

- Transfer Session “From Idea to Practice”

Deadline abstract submission for oral presentations: April 30, 2024

Deadline abstract submission for poster presentations: September 30, 2024

Partner countries for 2024 are Belgium, Netherlands and Luxembourg.

Deutsche Institute für Textil- und Faserforschung Denkendorf