Pincroft: Innovative non-skin contact vector protection for military fabrics

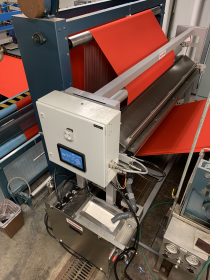

Pincroft announced the adoption of an innovative precision spray technology that allows the application of many finishes for textiles, including permethrin for vector protection, to the face of the fabric to avoid contact with the skin.

The system is a more versatile and environmentally friendly alternative to the traditional application method of padding and offers the possibility of applying the chemistry on either face side or both sides of the fabric across the full width.

The benefits of this new equipment are countless not only for the end user but also for the environment. The system allows for a reduction of energy, water and wet pick up of up to 50%, while 100% of the chemistry is recycled. Thanks to the equipment’s precision application technology, less water and chemistry are needed, and its no immersion system means the fabric would require less saturation and a shorter drying time.

Mike Collins, Pincroft’s Managing Director: “This innovative equipment can be used in two ways. The single sided spray finishing can be used where the full effectiveness of the finish is only required on the face side of the end item, for example, vector, fluorocarbon and antimicrobial protection. The dual spray finish may be used to simulate the traditional padding method where full effectiveness of the finish is required dependant on end use, for instance, crease recovery, fabric softening, soil release and moisture management.”

This vector protection solution provided by Pincroft is ACTIGARD®, a branded technology developed by Sanitized AG, with long lasting active ingredients that have proved highly effective against mosquitoes and ticks. This product endures a high number of washes, is suitable for military uniforms and conforms to Standard 100 by Oeko-Tex®.

Pincroft