Bacteria, eating Plastic and producing Multipurpose Spider Silk

For the first time, researchers have used bacteria to “upcycle” waste polyethylene: Move over Spider-Man: Researchers at Rensselaer Polytechnic Institute have developed a strain of bacteria that can turn plastic waste into a biodegradable spider silk with multiple uses.

Their new study marks the first time scientists have used bacteria to transform polyethylene plastic — the kind used in many single-use items — into a high-value protein product.

That product, which the researchers call “bio-inspired spider silk” because of its similarity to the silk spiders use to spin their webs, has applications in textiles, cosmetics, and even medicine.

“Spider silk is nature’s Kevlar,” said Helen Zha, Ph.D., an assistant professor of chemical and biological engineering and one of the RPI researchers leading the project. “It can be nearly as strong as steel under tension. However, it’s six times less dense than steel, so it’s very lightweight. As a bioplastic, it’s stretchy, tough, nontoxic, and biodegradable.”

All those attributes make it a great material for a future where renewable resources and avoidance of persistent plastic pollution are the norm, Zha said.

Polyethylene plastic, found in products such as plastic bags, water bottles, and food packaging, is the biggest contributor to plastic pollution globally and can take upward of 1,000 years to degrade naturally. Only a small portion of polyethylene plastic is recycled, so the bacteria used in the study could help “upcycle” some of the remaining waste.

Pseudomonas aeruginosa, the bacteria used in the study, can naturally consume polyethylene as a food source. The RPI team tackled the challenge of engineering this bacteria to convert the carbon atoms of polyethylene into a genetically encoded silk protein. Surprisingly, they found that their newly developed bacteria could make the silk protein at a yield rivaling some bacteria strains that are more conventionally used in biomanufacturing.

The underlying biological process behind this innovation is something people have employed for millennia.

“Essentially, the bacteria are fermenting the plastic. Fermentation is used to make and preserve all sorts of foods, like cheese, bread, and wine, and in biochemical industries it’s used to make antibiotics, amino acids, and organic acids,” said Mattheos Koffas, Ph.D., Dorothy and Fred Chau ʼ71 Career Development Constellation Professor in Biocatalysis and Metabolic Engineering, and the other researcher leading the project, and who, along with Zha, is a member of the Center for Biotechnology and Interdisciplinary Studies at Rensselaer.

To get bacteria to ferment polyethylene, the plastic is first “predigested,” Zha said. Just like humans need to cut and chew our food into smaller pieces before our bodies can use it, the bacteria has difficulty eating the long molecule chains, or polymers, that comprise polyethylene.

In the study, Zha and Koffas collaborated with researchers at Argonne National Laboratory, who depolymerized the plastic by heating it under pressure, producing a soft, waxy substance. Next, the team put a layer of the plastic-derived wax on the bottoms of flasks, which served as the nutrient source for the bacteria culture. This contrasts with typical fermentation, which uses sugars as the nutrient source.

“It’s as if, instead of feeding the bacteria cake, we’re feeding it the candles on the cake,” Zha said.

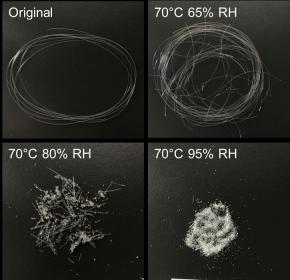

Then, as a warming plate gently swirled the flasks’ contents, the bacteria went to work. After 72 hours, the scientists strained out the bacteria from the liquid culture, purified the silk protein, and freeze dried it. At that stage, the protein, which resembled torn up cotton balls, could potentially be spun into thread or made into other useful forms.

“What’s really exciting about this process is that, unlike the way plastics are produced today, our process is low energy and doesn’t require the use of toxic chemicals,” Zha said. “The best chemists in the world could not convert polyethylene into spider silk, but these bacteria can. We’re really harnessing what nature has developed to do manufacturing for us.”

However, before upcycled spider silk products become a reality, the researchers will first need to find ways to make the silk protein more efficiently.

“This study establishes that we can use these bacteria to convert plastic to spider silk. Our future work will investigate whether tweaking the bacteria or other aspects of the process will allow us to scale up production,” Koffas said.

“Professors Zha and Koffas represent the new generation of chemical and biological engineers merging biological engineering with materials science to manufacture ecofriendly products. Their work is a novel approach to protecting the environment and reducing our reliance on nonrenewable resources,” said Shekhar Garde, Ph.D., dean of RPI’s School of Engineering.

The study, which was conducted by first author Alexander Connor, who earned his doctorate from RPI in 2023, and co-authors Jessica Lamb and Massimiliano Delferro with Argonne National Laboratory, is published in the journal “Microbial Cell Factories.”

Samantha Murray, Rensselaer