JUMBO-Textil: High-tech textiles for exoskeletons

Production and care, logistics and agriculture – people in these and many other industries work hard day after day. Exoskeletons offer them enormous relief in this regard. And in rehabilitation, these innovative "power suits" help patients expand their motor capabilities and extend their mobility. The central component of the exoskeleton is elastic narrow textiles.

Every gram counts

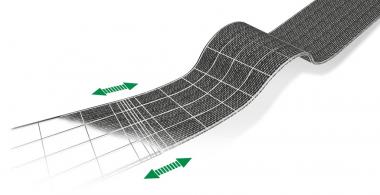

Exoskeletons also require lightweight components. And every gram counts here. Textiles are particularly light materials in themselves and JUMBO-Textil's elastics are also suitable for replacing heavier parts made of or containing plastic or metal. For example, they replace springs, buckles or other fasteners.

Good for your back – and your skin

Exoskeletons need skin-friendly components. Depending on the model and ambient temperature, exoskeletons are also worn directly on the skin. This is why JUMBO-Textil does not compromise when it comes to wearing comfort: whether elasticated hook-and-loop belts or slip-proof woven tapes, the surface of the textiles is pleasantly soft. And to prevent moisture accumulating, the textiles are always permeable to air. They are free from harmful substances and meet OEKO-TEX Standard 100 PK1.

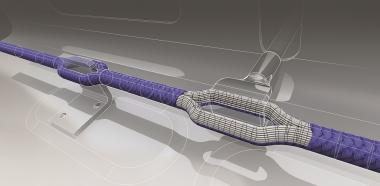

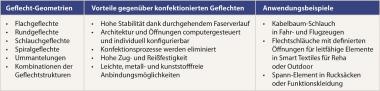

Innovative production technology – complex textile architecture

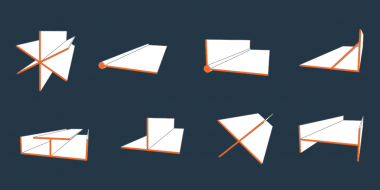

Exoskeletons need safe and stable components. JUMBO-Textil's production technology is always state-of-the-art. This allows for very different, and complex stable textile structures – from elastic buttonhole braids to multi-branched elastic hole cords.

JUMBO-Textil GmbH & Co. KG / stotz-design.com