Graniteville Specialty Fabrics installs Baldwin’s TexCoat™ G4

Graniteville Specialty Fabrics has set new standards by challenging the traditional pad finishing process. With Baldwin Technology’s spray finishing technology, Graniteville Specialty Fabrics has been able to increase production efficiency, and minimize chemical and water waste.

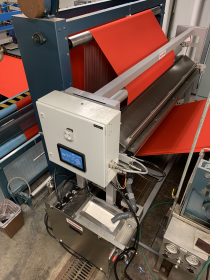

Based in Graniteville, South Carolina, Graniteville Specialty Fabrics produces coatings and coated fabrics that are resistant to water, fire, UV and weather for the military, marine and tent markets. The installation of Baldwin’s TexCoat™ G4 is part of a facility upgrade to maximize production efficiency and capacity in the durable water-repellent finishing and coating line to meet growing customer demand for advanced engineered products.

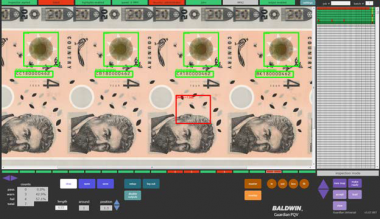

With sustainability benefits, tracking and process control, and Industry 4.0 integration, the TexCoat™ G4 provides high-quality fabric finishing, with no chemistry waste, as well as minimal water and energy consumption. This system utilizes non-contact precision-spray technology, ensuring precise finishing coverage with the exact amount of chemistry. Changeovers (pad bath emptying, cleaning and refilling) are reduced, resulting in substantial chemical conservation and increased productivity.

Graniteville Specialty Fabrics Baldwin Baldwin Technology Company Inc. TexCoat G4 textile finishing finishing technology

Baldwin Technology Company Inc.