Schoeller Textil with new recycled textile collection at PERFORMANCE DAYS in Munich

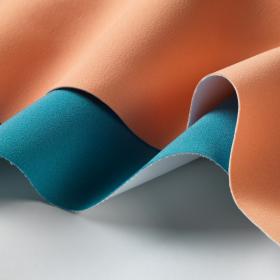

Textile performance inspired by nature - Swiss textile manufacturer Schoeller Textil AG launches the sustainable textile collection RE-SOURCE as part of its brand sustainability strategy. All textile innovations in the collection are made from bio-based, post- as well as pre-consumer materials such as recycled polyester and spandex. These are further enhanced with Schoeller textile technologies to provide the wearer with breathability, thermal regulation and wind and water repellency.

Two textile innovations in the collection have been lined on the inside with natural NATIVA Merino wool, produced under the highest sustainability standards. The manufacturing process of NATIVA Merino wool is 100% transparent and traceable for consumers through blockchain technology. NATIVA farms worldwide meet strict social and environmental requirements for animal welfare (ban on mulesing), land management and ethical labour guidelines.

Schoeller is committed to the CODE OF CONDUCT, which guarantees transparent production chains, environmental protection and fair working conditions. All RE-SOURCE textile innovations are bluesign approved - the international standard for responsible and sustainable textile manufacturing.

"The special Q-cycle process was used for RE-SOURCE. The resistant and durable Q-cycle polyamide is obtained by pyrolysis of used tyres and thus saves Co2 emissions compared to the combustion process. In this way, we are helping to protect the climate with Q-cycle," says Hans Kohn, COO, Schoeller Technologies AG.

The new recycled textile collection will be presented at the PERFORMANCE DAYS textile trade fair in Munich from 15-16 March 2023.

Schoeller Textil AG