Autoneum’s Re-Liner nominated as finalist for 2023 PACE Award

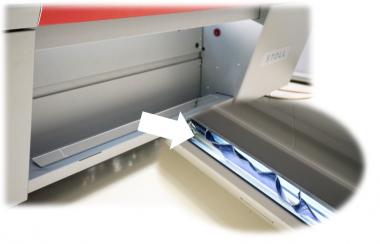

Using recovered resin from discarded car bumpers, Autoneum’s sustainable Re-Liner technology transforms a previously unusable waste product into lightweight and durable wheelhouse outer liners. In addition to their high recycled content, the eco-friendly components require significantly less energy to produce than conventional alternatives. The innovation presents another important step towards a more sustainable circular economy and has now been nominated for the 2023 PACE Award.

Autoneum has been selected as one of the finalists for the 2023 Automotive News PACE Awards. Entering its 29th year, this prestigious award honors superior innovation, technological advancement and business performance among automotive suppliers.

Re-Liner is based on a core of polyolefins recovered from post-consumer bumpers and has a textile top layer made of fibers from recycled materials. “Autoneum has recognized the untapped potential of recovered resin from automotive bumper covers as a resource and is giving this former waste product a second life,” explained Dan Moler. “The core resin of Re-Liner is 100% automotive post-consumer recycled material, not just a filler or additive to a virgin material. Lightweight, durable, and sustainable wheelhouse outer liners based on this technology are expected to reduce waste generated by bumper covers by nearly one million kilograms in 2023.”

For more than a quarter century of a century, the PACE Award has honored innovations driven by automotive suppliers. The award is known in the global automotive industry for identifying and recognizing the latest game-changing innovation: from the plant floor to the product to the showroom. In 2000, Autoneum (then Rieter Automotive) already received a PACE Award for its Ultra-Light technology. In addition, two of the Company’s technologies have also been nominated as finalists in the past: Ultra-Silent in 2010 and Theta-Fiber in 2012.

Autoneum