ISKO opens CREATIVE ROOM GERMANY

- First product development centre in Germany

ISKO has opened its second product development centre, based in Stade, Lower Saxony, following the success of the Creative Room London in the UK which had its opening earlier this year.

Creative Room Germany is a innovative space and the first of its kind in Germany. It is the latest initiative of Creative Room Services (CRS), a division of ISKO devoted to offering streamlined and simplified solutions for all denim requirements – from fabric to finished garment.

With a focus on sustainable washing and finishing techniques, customers of Creative Room Germany will be able to work in parallel with ISKO’s experts to achieve their desired denim looks. Together with machine technology partner Jeanologia, they have been able to develop innovative washing and finishing techniques that meet the highest quality and sustainability standards with a significantly lower environmental impact. Creative Room Germany will also be the central point for its customers full product development, ensuring the whole process is agile and more efficient.

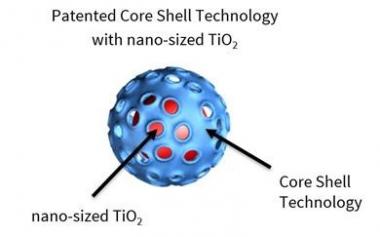

By utilising ISKO’s patented recycling technology, they are now able to develop brand new garments by using fibres from post-consumer denim, finally closing the loop and giving a new and cutting-edge circular supply solution for their customers. As well as a hub for its customers, Creative Room Germany will also act as a platform for the wider denim community to share knowledge, create new and innovative ideas and to bring them to life.

“Building on from the success of our London facility, our goal will be to offer tailor made garment supply solutions for customers in the DACH, Benelux and Nordic markets and this facility will be the focal point of that offering. With a collaborative approach, we will fulfil our vision of bringing a new circular supply solution to the market.”

Pau Bruguera, Executive Director @ ISKO

ISKO