AZL: Gemeinsames Projekt zu Batteriegehäusen mit 46 Industriepartnern

Gemeinsam mit insgesamt 46 Industriepartnern konnten mehrere, verschiedene Konzepte für Kunststoff-basierte Multimaterial-Batteriegehäuse erarbeitet werden, mit denen deutliche Einsparpotentiale bei Gewicht und Kosten möglich sind. Im Projektverlauf kristallisierten sich zwei wichtige Kernthemen heraus, die in Folgeprojekten gesondert behandelt werden sollen: Bodenaufprallschutz und Feuerbeständigkeit. Diese zwei Folgeprojekte starten am 26. Januar 2022. Ein Projekt zur Entwicklung und Realisierung von Prototypen für Mitte nächsten Jahres 2022 ist in Planung.

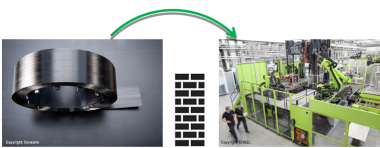

Batteriegehäuse gehören zu den Schlüsselkomponenten in E-Fahrzeugen und werden derzeit in der Regel aus Aluminium hergestellt. Genau diese Komponente analysierte das AZL in dem jetzt durchgeführten Projekt mit einem großen Konsortium aus Automobilherstellern, Automobilzulieferern, Rohstoffherstellern und Maschinenherstellern. „Der enorme Zuspruch aus der Industrie unterstreicht die Relevanz des Themas“, freut sich der Projektleiter Warden Schijve, der zudem sehr zufrieden mit dem Verlauf und den Ergebnissen ist. Schließlich lassen sich bis zu 36 % des Gewichts und bis zu 20 % der Kosten einsparen, wenn anstelle herkömmlicher Lösungen Multi-Material-Verbunde auf Basis von Kunststoffen zum Einsatz kommen.

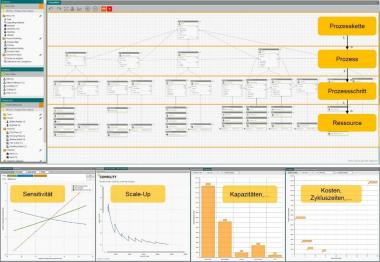

Um zu den Ergebnissen zu gelangen, hat das AZL unter Mitwirkung seiner Partnerunternehmen, zu denen unter anderem Audi, Asahi Kasei, Covestro, DSM, EconCore, Faurecia, Formosa, Hengrui, Hutchinson, IPTE, Johns Manville, Magna, Marelli und Teijin, gehörten, zunächst fünf Subkomponenten eines Batteriegehäuses definiert: die Gehäusewanne, die Bodenschutzplatte, den Crash-Rahmen, die Querbalken und den Gehäusedeckel. Außerdem analysierten die Partner insgesamt 44 marktrelevante, existierende Serienkomponenten und Konzepte genauer und erstellten eine umfangreiche Übersicht über die verschiedenen Standards sowie Anforderungen auf nationaler, internationaler und OEM-Ebene. Prämisse dabei war, gleiche oder gar bessere mechanische Kennwerte zu erreichen als bei herkömmlichen Lösungen. So sollten beispielsweise mindestens gleiche Steifigkeiten, Sicherheiten bei seitlichem Aufprall, EMI-Abschirmung sowie Flammschutz vorhanden sein. Um nun die alternativen Lösungen zu ermitteln, entwickelte das AZL 20 Designkonzepte mit unterschiedlichen Materialkombinationen. Zur Analyse und Auslegung der verschiedenen Konzepte wurden mehr als 500 FEM-Modelle erstellt und über 1.500 CAE-Simulationen durchgeführt.

Während sich Folgeprojekt 1 mit einer anwendungsbezogenen Testmethode und der Untersuchung der Sicherheit verschiedener Materialkombinationen für den Bodenaufprallschutz beschäftigt, steht in Folgeprojekt 2 die Flammresistenz verschiedener Materialien und Materialkombinationen im Vordergrund. Ziel ist es Prüfverfahren zu entwickeln, die es erlauben, die Aufprall-/Feuerbeständigkeit auf Materialebene unter Berücksichtigung der spezifischen Anforderungen an ein Batteriegehäuse im Vergleich zu Standardmaterialien zu untersuchen.

Firmen mit Interesse an Herstellung von Batteriegehäusen können sich an Philipp Fröhlig und Alexander Knauff wenden:

Philipp Fröhlig, AZL Aachen GmbH, Senior Project Manager, Tel: +49 241 47573514, philipp.froehlig@azl-aachen-gmbh.de

Alexander Knauff, AZL Aachen GmbH, Manager Industrial Services, Tel: +49 241 47573516, alexander.knauff@azl-aachen-gmbh.de

AZL Aachen GmbH