Clothing embedded with 1,200 tiny solar panels

- The future of wearable tech

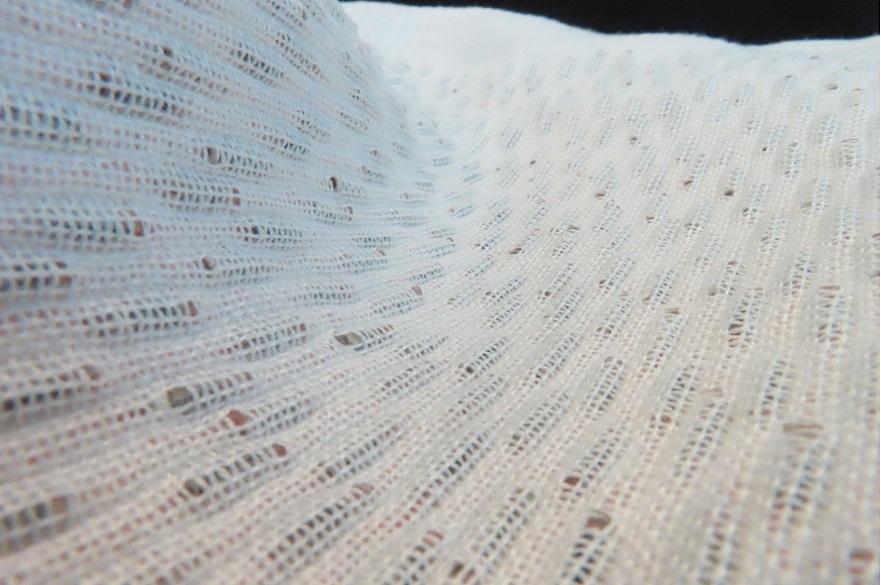

Textiles embedded with more than a thousand miniature solar cells - which are capable of charging a smart watch or mobile phone - have been developed by researchers at Nottingham Trent University.

Research overseen by Dr Theodore Hughes-Riley, associate professor of Electronic Textiles at the Nottingham School of Art & Design, has led to the development of a woven textile embedded with 1,200 photovoltaic cells.

The e-textile is an advanced prototype which could be incorporated into a piece of clothing such as a jacket, or used as part of an accessory such as a backpack. The cells combined together are capable of harnessing 400 milliwatts (mWatts) of electrical energy from the sun – enough to charge a basic mobile phone or smartwatch.

Fitted with strong but very flexible wiring, it is designed to be exposed to the same forces as everyday clothing and can be washed in a machine at 40°C with other laundry.

The solar cells - which measure only five millimetres in length and 1.5 millimetres in width - are embedded in a waterproof polymer resin and cannot be felt by the wearer.

“This prototype gives an exciting glimpse of the future potential for e-textiles,” said Dr Hughes-Riley, of the university’s Advanced Textiles Research Group (ATRG).

“Until now very few people would have considered that their clothing or textiles products could be used for generating electricity," explains Hughes-Riley. “And the material which we have developed, for all intents and purposes, appears and behaves the same as any ordinary textile, as it can be scrunched up and washed in a machine. But hidden beneath the surface is a network of more than a thousand tiny photovoltaic cells which can harness the sun’s energy to charge personal devices. Electronic textiles really have the potential to change people’s relationship with technology, as this prototype shows how we could do away with charging many devices at the wall. This is an exciting development which builds on previous technologies we have made and illustrates how it can be scaled up to generate more power.”

The material - which measures 51cm by 27cm - is breathable and chemically stable as all the solar cells are made from silicon. Tests showed that the material generated a power output of 335.3 mWatts in 0.86 sunlight. Under 1.0 sun it would generate up to 394 mWatts.

The project team included Dr Neranga Abeywickrama, who worked as a postdoctoral research fellow in Energy Harvesting and Management in Textiles, and PhD candidate Matholo Kgatuke, research associate in the Weaving of Electronic Textiles.

Ms Kgatuke, of the Nottingham School of Art & Design, said: “This project shows how e-textiles can be at the forefront of sustainability and that they have the potential to reshape our existing conceptions of technology. We have combined long-established weaving techniques with modern technology to create future products which may change people’s perceptions of clothing and electronics.”

Nottingham Trent University