Skin contact and remote hugs via smart textiles

Smart textiles are making virtual reality more immersive and enabling wearers to experience the sensation of physical touch. An ultrathin film that can transmit touch sensations is able to turn textiles into a virtual second skin. For seriously ill children in hospital isolation wards, this new technology offers them the chance to feel the physical closeness of their parents during computer-simulated visits and to experience again the feeling of being held, hugged or cuddled.

The research team led by Professors Stefan Seelecke and Paul Motzki from Saarland University will be presenting the technology behind these smart textiles at Hannover Messe from 22 to 26 April.

A hand on a shoulder, the stroke of an arm or a simple hug. Human touch can bring calm, comfort and closeness, a sense of safety and of being protected. When the nerve cells in our skin are stimulated by touch, numerous parts of our brain are triggered, causing immediate changes in our body's biochemistry. Hormones and signalling molecules are released, including oxytocin, which creates a sense of well-being and bonding. Video calls, on the other hand, tend to leave us cold. We miss the closeness and emotional connection that in-person meetings produce. But what happens when physical closeness is essential, when children are seriously ill, but their parents are unable to visit? When physical contact is not possible due to a weakened immune system?

An interdisciplinary research team at Saarland University, htw saar University of Applied Sciences, the Centre for Mechatronics and Automation Technology (ZeMA) and the German Research Center for Artificial Intelligence (DFKI) is working on a technology that will enable children in hospital isolation wards to feel in a very natural way the close physical proximity of their parents during virtual visits. The 'Multi-Immerse' project is at the interface of engineering science, neurotechnology, medicine and computer science and the members of the research team are developing ways to realize multi-sensory virtual encounters between individuals. The aim is to create new technology that will allow young patients to see, hear and feel their parents and siblings in as realistic a manner as possible so that the children experience a strong sense of close physical interaction even though they are physically separated.

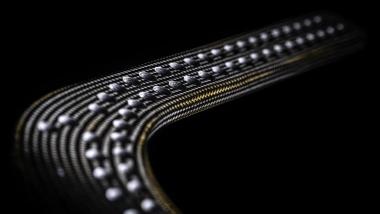

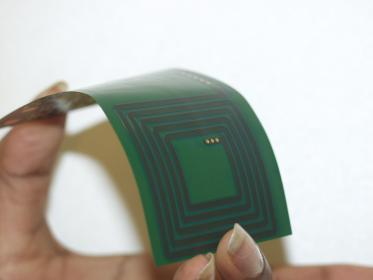

The research group led by Professors Stefan Seelecke and Paul Motzki at Saarland University and ZeMA in Saarbrücken is responsible for the tactile side of the project and for creating technical systems that deliver a realistic sense of touch. The Saarbrücken engineers are experts in using thin silicone films to impart novel capabilities to surfaces. They have developed films that are a mere 50 micrometres thick and that can be worn like a second skin. Just as our skin is our body's interface to the outside world, these ultrathin films are the body's interface to the virtual world. The goal is to create a lifelike sensation of touch from interactions between people in a virtual environment.

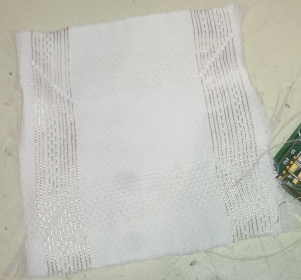

When incorporated into textiles, these high-tech films allow the child to experience being touched when the mother or father strokes a second smart textile elsewhere. 'The films, known as dielectric elastomers, act both as sensors – detecting the tactile input from mum or dad – and as actuators – that transmit these movements to the child,' explained Professor Seelecke, who heads the Intelligent Material Systems Lab at Saarland University. When functioning as a sensor, the film is able to recognize with very high precision how a hand or finger presses or stretches the film as it brushes over it. This physical deformation caused by the parent's hand is then reproduced exactly in a second textile that is in contact with the child's skin – giving the child the realistic impression of being stroked on the arm, for example.

‘A highly flexible electrically conducting layer is printed onto each side of the ultrathin film to create what is known as a dielectric elastomer. If we apply a voltage to the elastomer film, the electrodes attract each other, compressing the polymer and causing it to expand out sideways, thus increasing its surface area,' said Professor Paul Motzki, who holds a cross-institutional professorship in smart material systems for innovative production at Saarland University and at ZeMA. Even the slightest movement of the film alters its electrical capacitance, which is a physical quantity that can be precisely measured. When a finger runs over the film, the film deforms and an exact value of the electrical capacitance can be assigned to each individual position of the film. A sequence of these measured capacitance values represents the path taken by the finger as it moves. The film is therefore its own flexible sensor that can recognize how it is being deformed.

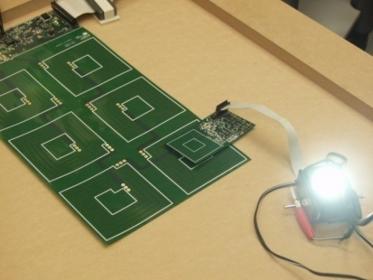

By knowing how capacitance values and film deformations correlate, the researchers can use the smart textile to transfer the stroking motion of a parent's hand to the child's arm. The research team is able to precisely control the motion of the elastomer film. By combining the capacitance data and intelligent algorithms, the team has developed a control unit that can predict and program motion sequences and thus precisely control how the elastomer film deforms. 'We can get the film to perform continuously controlled flexing motions so that it exerts increasing pressure on the skin, or we can get it to remain in a fixed position”, explained PhD student Sipontina Croce, who is carrying out doctoral research in the project. They can also create tapping movements at a specified frequency. The amplitude and frequency of the motion can be precisely regulated.

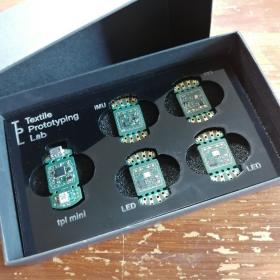

At this year's Hannover Messe, the team will be demonstrating their technology with a “watch” that has a smart film applied to its back. 'We can create chains of these smart components so that they can transmit long stroking motions. To do this, we interconnect the components so that they can communicate and cooperate collectively within a network,' explained Paul Motzki.

This smart-textile technology is inexpensive, lightweight, noiseless and energy-efficient. By providing a tactile element to computer gaming, the novel elastomer-film technology can also be used to make the gaming experience more realistic. In related projects, the engineers have used their technology to create interactive gloves for future industrial production processes, or to create the sensation of a tactile 'button' or 'slider' on flat glass display screens, which is literally bringing a new dimension to touchscreen interactions.

At this year's Hannover Messe, the experts for intelligent materials from Saarbrücken will be showcasing other developments that make use of dielectric elastomers, such as sensory shirts or shoe soles, or industrial components like pumps, vacuum pumps and high-performance actuators.

Universität des Saarlandes