Interview with Sonia Wedell-Castellano about DOMOTEX 2020

- Sonia Wedell-Castellano, Global Director of DOMOTEX,answers key questions on DOMOTEX 2020

- "We're the world's flagship fair: At DOMOTEX, you can view the entire range of products from the global floor coverings industry."

As Global Director of DOMOTEX, you took over responsibility for DOMOTEX just over a year ago. What have you been able to accomplish so far?

In rapid response to the wishes voiced by our exhibitors and visitors, we have, for example, opted for changes in the fair's layout. Previously, premium suppliers were located in the immediate vicinity of the special Framing Trends showcase. They will now go back to their traditional market environments, in their respective halls. For visitors, this means shorter distances and easier on-site orientation. We are also addressing our target visitors in an even more differentiated and more targeted way. We have also reassessed the concept of our classic "Preview" press conferences, and are now touring key media cities, visiting editorial offices and organizing informal dinners, to which we invite exhibitors as well as partners and the press – a networking event with a view to 2020.

Nearly 97,000 square meters of space have already been sold for DOMOTEX 2020. Who are some of the more interesting exhibitors that visitors can look forward to at the event?

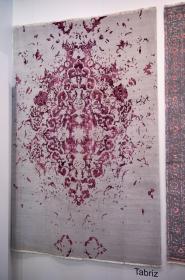

With some 1,500 exhibitors anticipated, the list is already quite long, so I'll only mention a few: Rug Star by Jürgen Dahlmanns, Naziri, Creative Matters, Galleria Battilossi, Rica Basagoiti will be showing in the handmade carpets segment. In the category of machine-woven carpets we are looking forward to Oriental Weavers, Carmel Carpet, Royal Hali, Prado Egypt, Stefany and Reinkemeier. US Floors, Windmöller, Moderna (MeisterWerke) and IVC will be exhibiting their resilient floor coverings, while ter Hürne, Decospan, BIMBO, SWISS KRONO and Forestry Timber will be presenting parquet, wood and laminate flooring. The manufacturers of installation technologies include Mapei, Selit, Välinge, Unifloor, Uzin Utz and Küberit.

What is the ratio of domestic to foreign exhibitors?

Of all Deutsche Messe events, DOMOTEX is by far the most international. This applies to exhibitors and visitors, alike. German exhibitors account for some 12% of display space, with the international share consequently running at 88%. This is naturally quite an achievement for the world's leading marketplace for floor coverings and carpets. That said, we also aim to expand our exhibitor lineup by attracting more exhibitors from Germany and the rest of Europe.

As a result of the changes made to the show's layout plan, Hall 8 will now be devoted entirely to the Framing Trends display. What can visitors expect to see there – and what's new?

Hall 8 will star as the pulsating, emotive heart of the event, with visitors being welcomed and wowed by a large textile horizon showing projections of atmospheric images. Our new lead theme of "ATMYSPHERE" will address how floors can improve our sense of well-being. In a series of Frames, we'll be showing the contribution that a floor's appearance makes to the overall atmosphere, how its texture dampens noise and how ecological production techniques make for a healthier indoor climate. Manufacturers, artists, universities and, for the first time, start-ups will take up these and numerous other characteristics to create soothing, personal worlds of experience via their creative approach.

Our partner agency, Schmidhuber will moreover be staging four pavilions consisting of furnished themed rooms, so as to make the lead theme even more tangible. "Hotel – Sustainable", for example, illustrates the impact of materials and furniture, including acoustic paneling in a hotel room. "Wellness – Green Living" emphasizes health-promoting and environmentally friendly aspects. "Conference – More than Floor" focuses on acoustic solutions, going all the way to upholstered seating landscapes, while "Health – Wellbeing" features a yoga room for relaxation. In the space between these focal points, the advantages of outdoor floors and a flowing transition from indoors to outdoors will be highlighted. The aim is not only to provide inspiration to designers, architects and retailers, but also to illustrate concrete areas of application.

Visiting professionals from retail, the skilled trades and architecture are among the main target groups at DOMOTEX. All of these groups have different needs and requirements. Apart from having interesting exhibitors, what will DOMOTEX be offering its attendees?

There will be something for everyone at the event. For top buyers from the wholesale and retail trades, we'll be offering a special service package to make their visit at DOMOTEX as pleasant as possible.

Craftspeople can look forward to a more state-of-the-art "Treffpunkt Handwerk" – a forum featuring issues ranging from the challenge of digitalization for the skilled trades and topics related to personnel and recruiting young talent to current product trends and cutting-edge application techniques. In addition, craftspeople can visit their associations here, such as the Federal Association for Parquets and Flooring Technology. In the adjacent live-action zones, our exhibitors will once again be giving practical tips on how to prepare and lay wooden floors.

As a special showcase, Hall 8 is ideal for architects and designers. On all four days of the event there will also be a wide range of presentations by renowned architects followed by discussions. This year for the first time ever, exhibitors can join in on staged panel discussions. The focus will be on the latest social transformations and their significance for architecture, in particular as it applies to floors. In specific terms, trendy topics such as building information modeling (BIM) or healthy living and working will be explored. In addition, AIT Dialog Tours – guided tours where internationally renowned architects and interior designers will share their personal highlights of DOMOTEX – will be conducted daily.

Exhibitors displaying new products and services for digitalization will be of interest to all three target groups. For retailers, this will consist of digital sales tools, for architects, the focus will be on building information modeling, and for craftspeople, interest will revolve around things like how to introduce an up-to-the-minute order database.

What do you see as the top USPs of DOMOTEX?

We are the world's only global business platform for carpets and floor coverings: At DOMOTEX, you can see and experience the entire range of products on offer by the global floor coverings industry.

Here you can get an overview of the latest trends and developments in the international market and keep abreast of the latest developments. Manufacturers and buyers as well as partners, architects and designers from all over the world come together at DOMOTEX. New business relationships and cooperation opportunities are emerging that were hitherto inconceivable. The show attracts visitors of extremely high caliber, nearly 90 percent of whom play a decisive role in their companies' buying decisions.

Deutsche Messe AG